The

implementation of the Start-Stop system in many newly manufactured vehicles is

causing major changes in power, charging and starting systems that should be

known by mechanics in order to avoid problems when working on them.

The

batteries used in today's cars, externally similar to traditional ones, may be

technologically different, so that the way of checking, recharging and

replacing them may be different. It should be remembered that the battery must

be adapted on replacement, in compliance with the manufacturer's procedures

both for recharging and for the connection of the jump start cables.

Due to the

need for good control of the electrical power supply system, the use of current

sensors located on the battery terminals (negative) is essential.

This allows the current input and output of the battery to be recorded so its capacity can be determined at any time, this means there are no risks of starting problems when the Start-Stop system decides to switch off the engine when the vehicle is stationary. This sensor reports battery voltage, temperature and current flow.

This allows the current input and output of the battery to be recorded so its capacity can be determined at any time, this means there are no risks of starting problems when the Start-Stop system decides to switch off the engine when the vehicle is stationary. This sensor reports battery voltage, temperature and current flow.

|

| Power sensors housed in the battery terminal |

Something similar happens with alternators. There are alternators found on the market that need to be stimulated to generate power, others will notify about their current level of power generation, and still others, called piloted, will receive the level of power to be generated from another control unit.

Attempts are being made to reduce the size and

weight of starter motors while increasing their reliability, as they must

withstand a higher number of operating cycles.

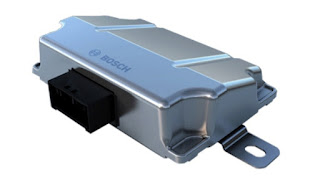

Start-Stop

systems introduce other elements, among which voltage stabilizers preventing

voltage drops at starting. Since certain comfort and audio-visual devices are

turned off during engine start, if voltage stabilizers were not incorporated, certain

elements of these systems could end up by being damaged.

|

| Servo brake pressure sensor |

As most

vehicles use vacuum type brake booster systems, called the servo-brake or power

assisted brake, it is essential that the system has a minimum depression in

order for braking to be effective, for this reason pressure switches or sensors

have been fitted at the servo-brake inlet, which provides information on the

existing vacuum level. If a low depression level is detected (under 400 mbar),

the engine is not stopped, or if it is stopped by action of the system, it will

be restarted.

One of the priority conditions for the system to operate is that the gearbox does not have an engaged gear; therefore, in vehicles with manual gearboxes a sensor must be fitted that informs the system unit if the gearbox is in neutral. In the case of automatic gearboxes, this sensor is already installed, therefore this information need only be sent to the control unit via the multiplexing network.

No comments:

Post a Comment