The AGM battery type application

in vehicles is becoming increasingly common because manufacturers equip their

vehicles with technological systems which require huge power supply for their

equipment.

It

should be noted that AGM batteries have become widely used as a result of the introduction

of vehicles fitted with the Start &

Stop system. As of today, most vehicles are equipped with this kind of

batteries due to their great performance.

What

is an AGM battery?

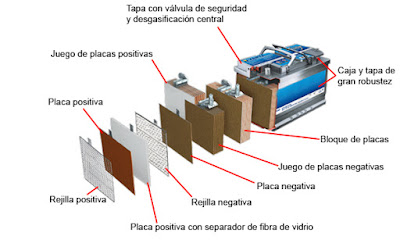

The AGM-type batteries belong

to the VRLA battery family which

stands for Valve Regulated Lead Acid, that is to

say, they are lead acid batteries regulated by valves.

Their constitution is similar to conventional batteries; they are wet lead calcium batteries. The AGM battery

has the same number of positive plates (lead peroxide) and negative plates (sponge

lead) and they provide a 12-Volt

nominal voltage.

The new

aspect of the AGM-type batteries is that they are based on a fibreglass grid placed between the

plates that absorb the electrolyte and the distilled water.

What are its characteristics?

- The electrolyte gases produced during the discharge and charge cycle

are transformed into water.

- The electrodes of the plates fix the fibreglass using pressure, which

means that the fibreglass is always in watertight and uniform contact with the

electrodes. In this way, the loss of

active mass caused by vibrations is minimized.

- In the case of water vapour generation, at high temperature (between 20 and 200 milibars), the system uses an overpressure valve which releases the gas to the atmosphere but prevents the entry of the atmospheric oxygen into the battery.

- The plates are larger in size than the conventional plates.

- The intensity of the energy interchange cycle (discharge and charge) may be up to three times greater due to the fiberglass separators.

- The battery acid is impregnated into the

fibreglass.

TYPE OF BATTERIES

|

|||

TECHNOLOGY

|

LEAD ACID

|

GEL

|

AGM

|

Voltage

|

12 V

|

6V and 12V

|

6V and 12V

|

Battery Capacity (Ah)

|

from 40 to 180

|

from 16 to 210

|

from 33 to 225

|

Cold Start Current EN (A)

|

from 330 to 920

|

from 180 to 1030

|

from 680 to 950

|

Mounting Angle

|

No inclination

|

Any position

|

Any position

|

Charge Requirement

|

DC, 10% of the capacity

|

DC, from 25% to 50% of the capacity

|

DC, any amperage

|

Discharge time

|

After 8 months, 35% of the charge is maintained

|

After 2 years, 85% of the charge is maintained

|

After 2 years, 90% of the charge is maintained

|

Service Life (charge/discharge cycle)

|

Between 350 and 400

|

Between 550 and 600

|

Between 950 and 1000

|

Maximum Discharge Power

|

Around 55% -60%

|

Around 75%

|

100%

|

Possibility of Electrolyte Loss

|

Possible loss of liquid

|

Possible loss of gel

|

None

|

Indicative Data

How does a car battery

work?

Battery Discharging

If a

consumer is connected to the battery, an external electric circuit is established

between the battery terminals due to the potential

difference between both plates and electrodes. The

different nature between them produces

the discharge.

The discharge consists in transforming

the chemical energy to electrical energy. In this way, an electron current

is produced and it circulates from the negative to the positive plate of the

battery at the exterior of the accumulator, and from positive to negative at

the interior (electrolyte).

Remember: The direction of the current is from (+) to (-). This direction is the conventional one, but the real direction is reverse, it is from (-) to (+).

The chemical decomposition occurs as follows:

the sulphuric acid breaks up in sulphate ions and hydrogen ions , the

sulphuric acid of which combines with the plates.

In the positive plate the lead peroxide is decomposed and transformed

into lead sulphate, and oxygen

is released as a result.

In the negative plate, the

sulphate reacts with the lead, so lead sulphate is also

formed. The oxygen

and hydrogen ions released in both reactions combine to form water, which is accumulated inside the

mixture as a part of the battery electrolyte. The electrolyte decomposition (water

+ sulphuric acid) decreases water density.

These

chemical transformations take place inside the battery, and generate electrical

current due to the alteration of the chemical elements between the two plates.

Battery Charging

Charging a battery reverses the chemical process that occurs during the

discharge. This process consists in transforming the electrical energy from a

generator (alternator) into chemical energy. The electrons circulate from the

positive to the negative plate, so a process reverse to the discharge is

produced.

The electrolyte

composition (water + sulphuric acid) increases water density.

The electrolyte water generated

during battery discharge is decomposed by electrolysis in ions (2H+) and (O2). The oxygen

of the water of these ions reacts with the lead of the positive plate. Thus,

the lead peroxide is formed again (PbO2). The

sulphate (SO4=) of both plates is released which makes the

hydrogen react with the sulphate, and sulphuric acid is formed again (H2SO4).

The electrolyte composition (water

+ sulphuric acid) increases water density.

The discharge and charge cycles which are produced inside the battery cause

the deterioration of the chemical elements that form the battery, limiting its

service life as reflected in the number of cycles.

No comments:

Post a Comment